At the transition stage to series production we are supported by our team of process and quality engineering as well by perfectly trained employees.

Manufacturing of Acoustic Products

Established in 1995, our manufacturing company Ningbo Kepo is an international joint venture with headquarters located in Ningbo, China. The company covers an area 16,000 square meters, combined with more than 900 employees. All acoustic products are manufactured in four factories in this area. Our main products include Piezoelectric Ceramic, Piezoelectric Sensor, Buzzers, Speakers & Receivers, Alarms & Horns and Microphones. In 4 factories over 900 skilled employees are working and allowing us to meet high volume demands of our OEM customers.

Factory 1

Factory 2

Factory 3

Factory 4

The production processes

A Sector of Engineering Technology has been set up in each different Division, to execute the Innovation and Improvements for Production Technology. As a result, we have already mastered several core technologies such as the Piezo electric element manufacturing technology, INSERT manufacturing technology, diaphragm manufacturing technology, plastic mold designing technology, equipment designing/manufacturing technology, software program design, and other fundamental technologies. All of these help us strengthen our core compentences. We possess the necessary equipment and apparatus for new product developments. Some of these are imported from South Korea, Japan and the United States. This helps us to meet the needs for all tests, measurements, evaluation and development of new products.

Continous proccess improving

The Engineering Technology Group (ETG) was set up a couple of years ago to implement the innovation and improvements for the production process. With continuous efforts, we have mastered the improvement of major core technologies, like the piezo element manufacturing technology, INSERT manufacturing technology, diaphram manufacturing technology, plastic mold designing technology, production equipment designing technology. We implemented successfully software program designs for monitoring all production process steps. We possess adequate equipment and apparatus imported from South Korea, Japan and the United States.

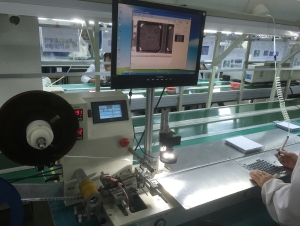

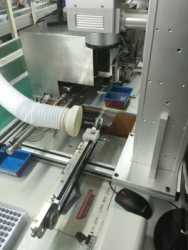

Critical production steps

To minimize human influences, we have fully or semi automated machines implemented for all critical production steps, thus enabling us to keep high levels of production quality.

Final product inspection

To minimize human influence on the production process, we execute all critical production steps like welding or product testing on fully or semi automated machines. The final product test procedure is done automatically by measuring parameters e.g. SPL, Impedance, Frq-curve etc. Only when the inspection results are "good", the automating code printing mashine EOL will mark the part number on the device. Otherwise the device will be phased out and not marked.

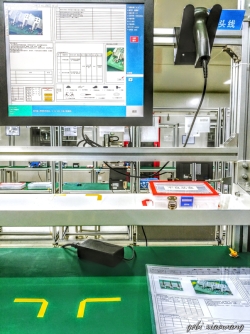

Tracability of production parametes

In our production, we have integrated automated data aquisition and data capturing of all relevant production processes. Each products has a barcode label an we can trace all the production parmeter at ny production steps. We are able to discover at a very early stage any parameter shifts in production, and can start immediate countermeasures to keep a constantly high production quality level. All data are stored in our MES computer system and can be used for later analyses (FMEA). We are considering to open this production related data to customer on a web access basis.