Highly specialised personnel are qualifying and testing our products. The basis of our solid quality level. We are fullfilling international automotive requirements.

Qualification

The qualification plays a very important role in our process of product development. Here we verify whether a product meets or exceeds the reliability and quality requirements with regard to its application.The internal quafification of our products follows international standards like ISO9001, TS16949 . The qualification occurs basically in 3 different stages:

-

Virtuel Qualification (Design)

Virtual qualification is the first stage of the overall qualification process. It is the application of PoF based reliability assessment to determine if a product can meet its calculated life cycle. This simulation based process assess reliability goals and life cycle based on its materials, geometry and operating characteristics. Our goal is to build in "quality" in our products at this early design stage.

-

Product Qualification (Prototype)

After first prototype manufacturing we start with the product qualification process. The intention is to qualify a product before starting mass production. This includes the verification of function and performance, the validation in application and the qualification for processability and reliability. This includes: technical specification, desing release, material check, function test,reliabilty test, product FMEA

-

Quality Assurance testing ( Mass production)

This testing take place during mass production and before the products are shipped to the customer. Our quality assurance testing ensures that the products are manufactured according to the design within the given tolerances. Accelerated stresses will be applied to the products to force early failures that are caused by manufacturing defects. This reflects: FMEA ,process flow chart , control plan, process capability, test equipment capabilty , supply chain status

Continously improving the process

The Engineering Technology Group (ETG) was set up a couple of years ago to implement the innovation and improvements for the production process. With continuous efforts, we have mastered the improvement of major core technologies, like the piezo element manufacturing technology, INSERT manufacturing technology, diaphram manufacturing technology, plastic mold designing technology, production equipment designing technology. We implemented successfully software program designs for monitoring all production process steps. We possess adequate equipment and apparatus imported from South Korea, Japan and the United States.

Product Qualification

Before the mass production can start the product undergoes a details qualification process. This includes the verification of function/performance, the processability and reliability. If it is applicable we examine a validation in the application environment. During all this stages we collect a bundel of information on the product configuration, materials, strength limits and margins. We evaluate the life cycle profile, do detailed failure analysis and reliability assessment. Here after we define the qualification requirements, do planning of tests and set up the testing procedure.

We perform all test on modern high quality equipment: temperature cycle test, climate test, Burn-in test, end-of-line test , vibraion-shock test etc. We stand for high quality in all sectors of our portfolio.

Humidity Test

Humidity Test

Life-Cycle Test

Temperature Test

Salt-Spray Test

Quality Assurance Testing

During mass production and before the products are shipped to the customer we perform continously qualification tests in the production lines to ensure that the products are manufactured according to the design and within specified tolerances. In order to guarante high quality level we put on each critical production step a in-line quality test to detect possibel failure at early stage. Furthermore, we apply increased stresses to the products to accelerate early failures that are caused by manufacturing defects. Below are some examples shown of critical production steps and where we introduced automatic production equipment and implemented additional quality control equipment.

Critical production steps

To minimize human influences, we have fully or semi automated machines implemented for all critical production steps, on our acoustic productionline thus enabling us to keep high levels of production quality.

Auto winding

Auto winding

Auto soldering

Auto soldering

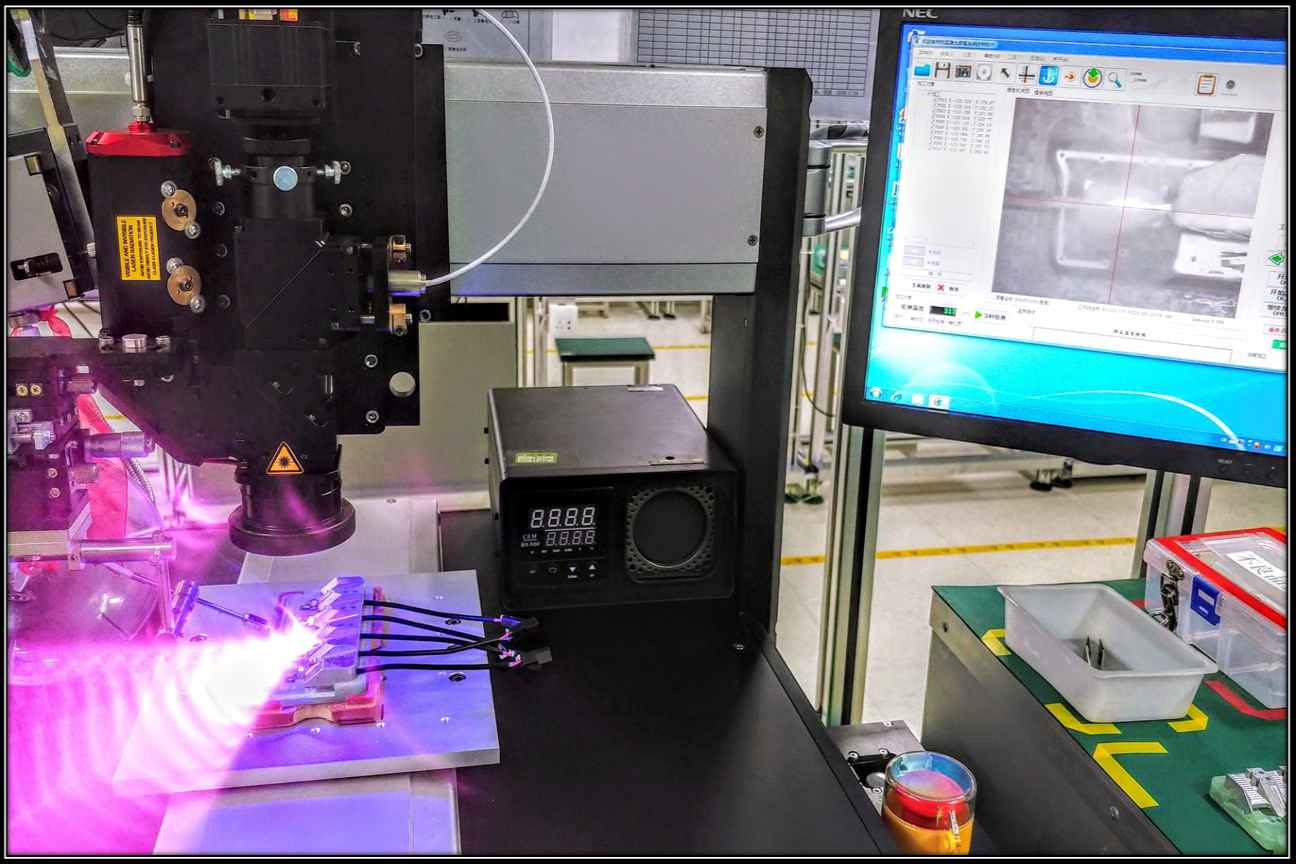

Auto lasering

Auto lasering

AOI inspection

AOI inspection

Product inspection in the production Line

The product test procedure is done automatically by measuring acoustic parameters e.g. SPL, Impedance, Frq-curve etc. Only when the inspection results are "good", the automating code printing mashine will mark the part number on the device. Otherwise the device will be phased out.

Auto welding

Auto welding

EOL-test

EOL-test

Auto soldering

Auto soldering

3D-glueing

3D-glueing

Soldering control

Soldering control

Impedance control

Impedance control

Auto final inspection

Auto final inspection

Data aquisition & product tracing

Data aquisition & product tracing Incoming material Inspection

( production of acoustic products)

|

3D-dimension control |

Taunt control |

ROHS inspection |