We are turning your ideas into products

Developing a new product is a complex process that requires a concerted effort, managing a project through the various stages of development. Contitec realizes this during the product definition, development and manufacturing stages. Our target is to provide the product you want to have with regard to the quality, functionality, and cost that are needed to make it a market success.

3D Simulation

Our speaker designers use simulation software to validate their designs before committing to prototypes and production runs. The simulation tools are based on finite element analysis (FEA) applications that provide basic one-, two- and three-dimensional modeling and simulation. This pairing of knowledge, experience and simulation tools leads to products that optimally fit your application environment.

Design & Development

... between our designers, engineers, and manufacturing specialists allows us to consider the effects that the design will have on the manufacturing phase at a very early stage. As a result, customers benefit from a product that is designed carefully for mass production from the beginning, and they can take advantage of cost reduction, reduced risks, and a shorter time-to-market.We have worked on numerous projects and this makes it possible for you to leverage our experience in developing customer specific products.

The Production

Established in 1995, our manufacturing company is an international joint venture located in Ningbo, China. The company covers an area 16,000 square meters, combined with more than 900 employees. All acoustic products are manufactured in four factories in the Shanghai area. Our main products include Piezoelectric Ceramic, Piezoelectric Sensor, Buzzers, Speakers & Receivers, Alarms & Horns and Microphones. In 4 factories over 900 skilled employees are working and allowing us to meet high volume demands of our OEM customers.

Factory 1

Factory 2

Factory 3

Factory 4

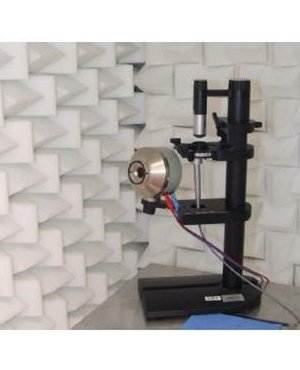

The production processes

A Sector of Engineering Technology has been set up in each different Division, to execute the Innovation and Improvements for Production Technology. As a result, we have already mastered several core technologies such as the Piezo electric element manufacturing technology, INSERT manufacturing technology, diaphragm manufacturing technology, plastic mold designing technology, equipment designing/manufacturing technology, software program design, and other fundamental technologies. All of these help us strengthen our core compentences. We possess the necessary equipment and apparatus for new product developments. Some of these are imported from South Korea, Japan and the United States. This helps us to meet the needs for all tests, measurements, evaluation and development of new products.

Continously improving the process

The Engineering Technology Group (ETG) was set up a couple of years ago to implement the innovation and improvements for the production process. With continuous efforts, we have mastered the improvement of major core technologies, like the piezo element manufacturing technology, INSERT manufacturing technology, diaphram manufacturing technology, plastic mold designing technology, production equipment designing technology. We implemented successfully software program designs for monitoring all production process steps. We possess adequate equipment and apparatus imported from South Korea, Japan and the United States.

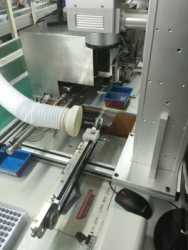

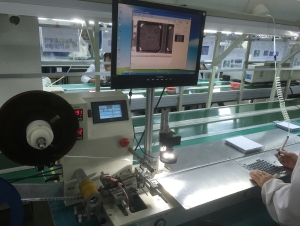

Critical production steps

To minimize human influences, we have fully or semi automated machines implemented for all critical production steps, thus enabling us to keep high levels of production quality.

automated soldering

autom. glue maschine

autom. membrane positioning

Final product inspection

To minimize human influence on the production process, we execute all critical production steps like welding or product testing on fully or semi automated machines. The final product test procedure is done automatically by measuring parameters e.g. SPL, Impedance, Frq-curve etc. Only when the inspection results are "good", the automating code printing mashine EOL will mark the part number on the device. Otherwise the device will be phased out and not marked.

EOL Auto Code Machine

Final Buzzer Test (automatic)

S.P.L,Fre. , Impedance

Automotive Solutions

We are highly dedicated and experienced to offer customized acoustic solutions for automotive applications, starting from simple alarm buzzer, customized mini speaker upt to piezo sounder system solutins for new electronic vehicals. All the above tasks have strengthened our core competetence and empower us today to operate a solid automotive production. Beside all necessary authorities' approval e.g. ISO16949, ISO 9001, ISO 14001, our factories are regularly audited by Tier1/Tier2 customers.

Reliability: at the right cost

With focus on automotive designs, our acoustic products deliver the right performance and reliability at the right cost. This is decisive for our success in the automotive component business. Today, we are diversifying our customer base and entering new automotive applications e.g. EV-cars, thus creating a dynamic growth-oriented environment.

Automotive Quality

We have established an integrity quality system and quality organization, and have set up a QC center responsible for the company's IQC, OQC, ROHS, and reliability tests. The entire company's product quality is under the center's monitor. We have also established quality management sectors in the company's various Divisions, taking charge of the IPQC, analysis of customer complaints, quality engineering, CPK, SPC quality statistics and analytics etc. In 1999, we approved the IS09001 quality system, and adopted the IS014001 environment system in 2005. In May 2007 we approved the ISO/TS16949: 2002 quality system, IATF Certificate Number: 0048630; CASC Certificate Number: 2007 A024. In accordance with the needs of customers, we also have the approved quality certification on CE, UL, E-MARK. We perform automotive level validation test standard e.g. VW80000 etc.

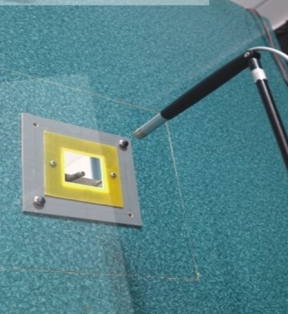

Clean room (Microphone-module production)

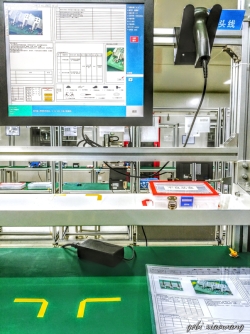

Tracability of production parametes

In our production, we have integrated automated data aquisition and data capturing of all relevant production processes. Each products has a barcode label an we can trace all the production parmeter at ny production steps. We are able to discover at a very early stage any parameter shifts in production, and can start immediate countermeasures to keep a constantly high production quality level. All data are stored in our MES computer system and can be used for later analyses (FMEA). We are considering to open this production related data to customer on a web access basis.

tracability scan

Data Aquisition

Parameter Capturing